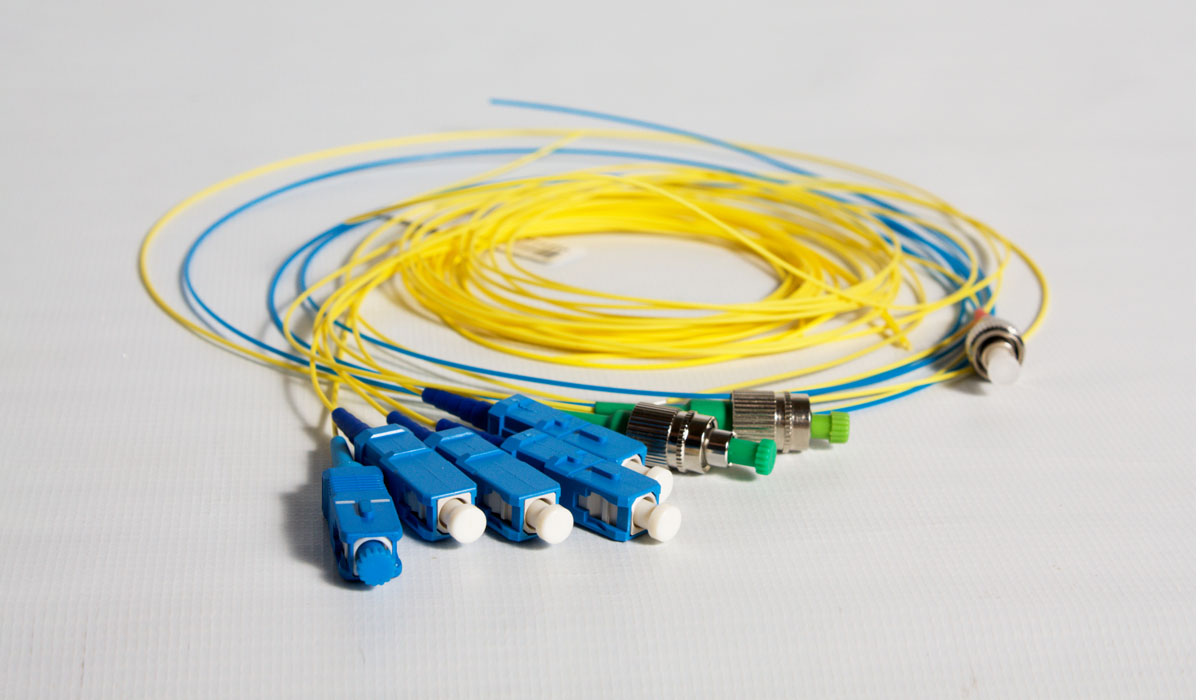

OSP Fiber Optic Installation All fiber optic applications are not the same. Testing the Installed Fiber Optic Cable PlantĪdministration, Management, and Documentation Preparing For Outside Plant Installations Role of the Contractor in an Installation Outside Plant Fiber Optic Cable Plant Installation Since the real fiber pulling environment could be more complex, the recommended procedures we offered above is a simple guideline, and I hope it can be helpful.The FOA Reference For Fiber Optics - Fiber Optic Installation During the process, installers should avoid cable damage, despoiling the fiber properly, and take pulling force into account. Pulling fiber optic cable is a dispensable and rather important part in fiber cable installation. You are now ready to terminate or add fiber connectors. Note: Leave enough cable at either end to reach the work-area and closet terminating locations. Step Six: After pulling fiber optic cable, cut off approximately 10 feet of cable from the pulling end to remove any portion of the cable that may have been stretched or damaged during installation. Also, use a tension meter to monitor the tension being applied to the cable during the pull. Step Five: Use a swivel when pulling fiber optic cable to make sure twists in the pull rope are not translated to the fiber-optic cable. This is done by sliding the grip past the end of the cable and then cutting the cable jacket back to expose the strength members. Step Four: With some cables, such as outside-plant cable, it may be necessary to attach the pulling grip to strength members that surround the cable core as well as the outer jacket. The load is applied to the strength members of the cable rather than the optical fiber, itself. This device locks onto and tightens around a cable as a tensile load is applied. Step Three: When additional mechanical force is needed for a pull, use external pulling grips. However, first make sure the pull does not exceed the tensile-loading limit established by the manufacturer for installation.

Step Two: In many runs, if the pulling distance is short enough and the pathway straight enough, fiber-optic cable can be pulled by hand, without the use of special equipment. Step One: Inspect the cable run to ensure there are no sharp bends or corners that exceed the minimum bend radius of the fiber. This cable has an overall PVC sheath and is not rated for plenum spaces. Indoor/Outdoor cables are not recommended for aerial installations. Indoor/Outdoor: Indoor/Outdoor cables are approved for use in underground conduits, even if the possibility of water infiltration exists. The only difference between outdoor (jell-filled) and direct bury cable is that the latter has an added overall metallic sheath which gives it protection from rodents. This cable is suitable for underground installation in conduit, overhead lashed to a guy wire, or secured to a building or other permanent outdoor structure. Outdoor: Outdoor cables are filled with a water blocking jell and are rated for all outdoor applications except for “direct bury”. A cable rated for plenum installation will have low-smoke characteristics. Indoor (Plenum): The cable is rated for all indoor installations, including plenum rated spaces.

When the cable is placed under a tensile load while being pulled, a minimum of 20 cable diameters is recommended. A minimum bending radius of 10 cable diameters must be maintained over long-term, static conditions. Another most common problem is bending the fiber on too tight a radius.

0 kommentar(er)

0 kommentar(er)